In the dynamic world of supply chain management, success hinges on efficiency and the ability to lower overhead and increase the bottom line. HJS Packaging and Distribution has helped numerous companies increase profits through their innovative solutions in private-label packaging, inventory management, global distribution, and order fulfillment services.

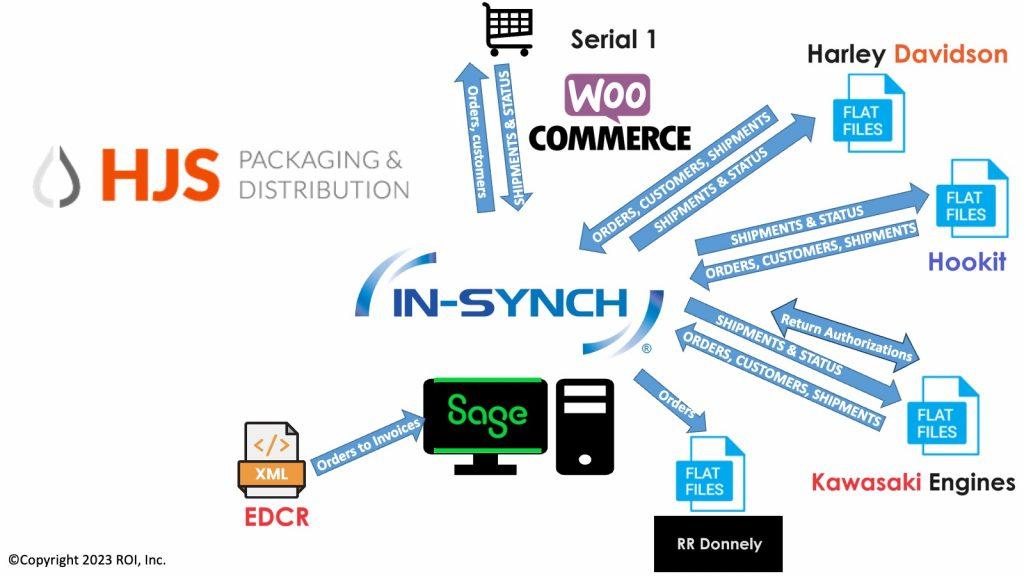

Since 1990, HJS has operated in the supply chain and distribution sector, specifically catering to dealerships. Notable clients include Harley Davidson, Kawasaki, and Serial One, a spinoff brand of Harley-Davidson dealing in electric bicycles. HJS uses Sage 100 as their ERP. Their Sage 100 technology partner, Vrakas/Blum Computer Consulting, recommended us as the best choice for an integration/automation partner.

Remarkably, HJS notes the same observations with their clients as us — “Companies are most successful when they can stay focused on running their business.” Just as HJS helps companies keep that focus by handling routine yet complex tasks, our integration solutions help HJS operations meet their objectives by automating manual tasks that speed up production and greatly minimize human errors. This has proven to be a defining tool for HJS to speed up production time and focus on delivering outstanding customer service.

IN-SYNCH Flexibility Meets Customer Demands

HJS has employed us in several major client projects to ensure smooth information flows. Our highly complex application, IN-SYNCH®, is written specifically for Sage 100 and enables an unlimited number of integrations to be connected. In addition, IN-SYNCH can be deployed in a variety of integration formats through ROI’s Integration Data Services. These features allow HJS to work with their clients’ specific technology needs to make the right connections.

Dean Beck, the VP and CFO of HJS, emphasizes how transformative the partnership with us and the IN-SYNCH solutions has been for his company. “I’ve worked with them on many integrations, and they’ve always been there to create the right solution and to help us out on issues, big or small, common or uncommon.” For example, HJS automated a return authorization process for a client through transferring flat files between Sage 100 and the client’s system. This not only automated the HJS side of the business process, but their client also experienced the same relief.

Dean points out that they opted for using a flat-file integration with IN-SYNCH instead of a full EDI solution because of its cost-effectiveness. The upfront development cost is offset by the efficiency and affordability of subsequent transactions. In fact, this capability has enabled HJS to offer a customized and cost-competitive solution to gain new business.

IN-SYNCH Enables Rapid Data Turnaround

In addition to being cost-effective, IN-SYNCH offers rapid turnaround of information. Orders are typically processed and closed within the same day. Purchase order information, including customer data and quantities, is brought into Sage 100. Shipment status is sent back to the client. RMAs are transferred between systems. Notably, pricing is handled within Sage 100, avoiding potential discrepancies.

Dean highlights the importance of IN-SYNCH in handling issues promptly, citing a specific instance where a logic statement for warehouse allocation needed adjustment. Our ability to swiftly communicate changes and implement them showcases the flexibility and effectiveness of IN-SYNCH.

Looking ahead, Dean expresses confidence in IN-SYNCH’s capability to adapt to HJS’s evolving needs. Despite challenges and uncertainties, the company relies on the continuous support and adaptability of IN-SYNCH.

HJS’s collaboration with us has not only streamlined operations but also positioned them as adaptable industry leaders. As the company continues to evolve, the partnership with us using IN-SYNCH remains a cornerstone for success in the ever-changing landscape of supply chain management.